What is Spunbond non-woven fabric and What is the difference between it and Melt-blown fabric

- Categories:Non-woven fabric News

- Author:

- Origin:

- Time of issue:2021-04-21

- Views:

(Summary description)Spunbond non-woven fabric is extruded and stretched polymer to form continuous filaments, and the filaments are laid into a net. The fiber net is then bonded by itself, thermally bonded, chemically bonded or mechanically reinforced to make the fiber net It becomes a non-woven fabric.

What is Spunbond non-woven fabric and What is the difference between it and Melt-blown fabric

(Summary description)Spunbond non-woven fabric is extruded and stretched polymer to form continuous filaments, and the filaments are laid into a net. The fiber net is then bonded by itself, thermally bonded, chemically bonded or mechanically reinforced to make the fiber net It becomes a non-woven fabric.

- Categories:Non-woven fabric News

- Author:

- Origin:

- Time of issue:2021-04-21

- Views:

Spunbond non-woven fabric is extruded and stretched polymer to form continuous filaments, and the filaments are laid into a net. The fiber net is then bonded by itself, thermally bonded, chemically bonded or mechanically reinforced to make the fiber net It becomes a non-woven fabric. It has the characteristics of good high temperature resistance, good low temperature resistance, aging resistance, UV resistance, high elongation, good stability and air permeability, corrosion resistance, sound insulation, mothproof, non-toxic and so on.

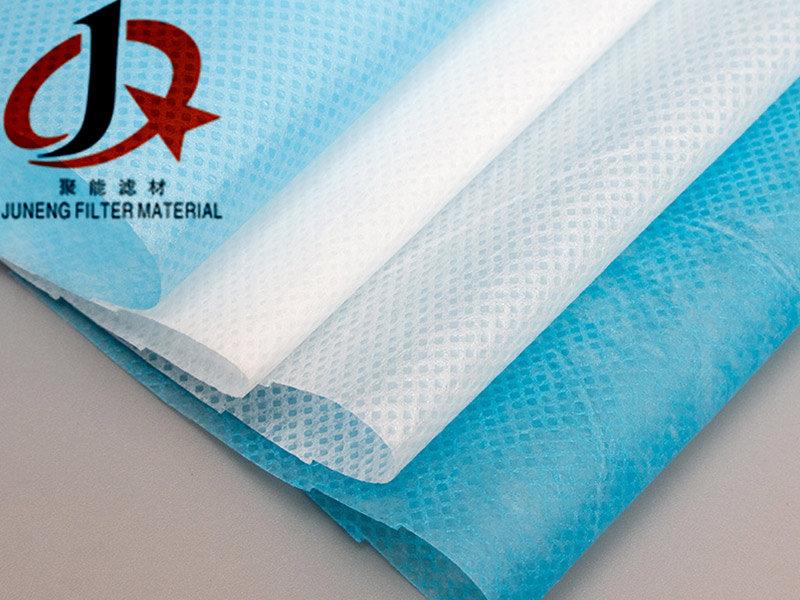

The main products of Spunbond non-woven fabric are polypropylene and polyester non-woven fabrics. Our most common and commonly used applications are non-woven bags, non-woven packaging, etc.; it is easier to identify Spunbond non-woven fabric, generally two-way The fastness is good. Generally, the rolling point of Spunbond non-woven fabric is diamond-shaped.

Melt-blown fabric uses polypropylene as the main raw material, and the fiber diameter is 1 to 5 microns. There are many voids, fluffy structure and good wrinkle resistance. The ultrafine fibers with unique capillary structure can increase the number and surface area of fibers per unit area, so that Melt-blown fabric has good filterability, shielding, heat insulation and oil absorption Sex. It can be used in the fields of air, liquid filter materials, isolation materials, absorption materials, mask materials, thermal insulation materials, oil absorption materials and wipe cloths.

Melt-blown fabric filter material is made of polypropylene microfibers randomly distributed and bonded together. The appearance is white, smooth and soft. The fiber fineness of the material is 0.5-1.0μm. The random distribution of fibers provides more thermal adhesion between the fibers. Therefore, the melt blown gas filter material has a larger specific surface area and a higher porosity (≥75%). After high-pressure electret filtration efficiency, the product has the characteristics of low resistance, high efficiency and high dust capacity.

Why Oil Absorbent Pads are Essential for a Safe and Clean Workplace

How to Choose the Right Oil Absorbent Pads for your Business

The Top 10 Oil Absorbent Pads for Industrial Applications

The Benefits of Using Wholesale Oil Absorbent Pads in the Filtration Industry

ADD:No.399 West Section Of Fucheng Avenue,Hi-Tech Zone,ChengDu,China

Key words:

Filter Material Adsorption Products Filter Adsorption Medical Accessories Medical Liquid Absorbent Pad Oil Absorbent Cotton Oil Absorbent Cord Graphene Respirator Mask Material PM2.5

©2021 Sichuan Juneng Filter Material Co.,ltd Copyright Powered by www.300.cn