How the Melt-blown fabric is constructed

- Categories:Melt-blown fabric News

- Author:

- Origin:

- Time of issue:2023-03-23

- Views:

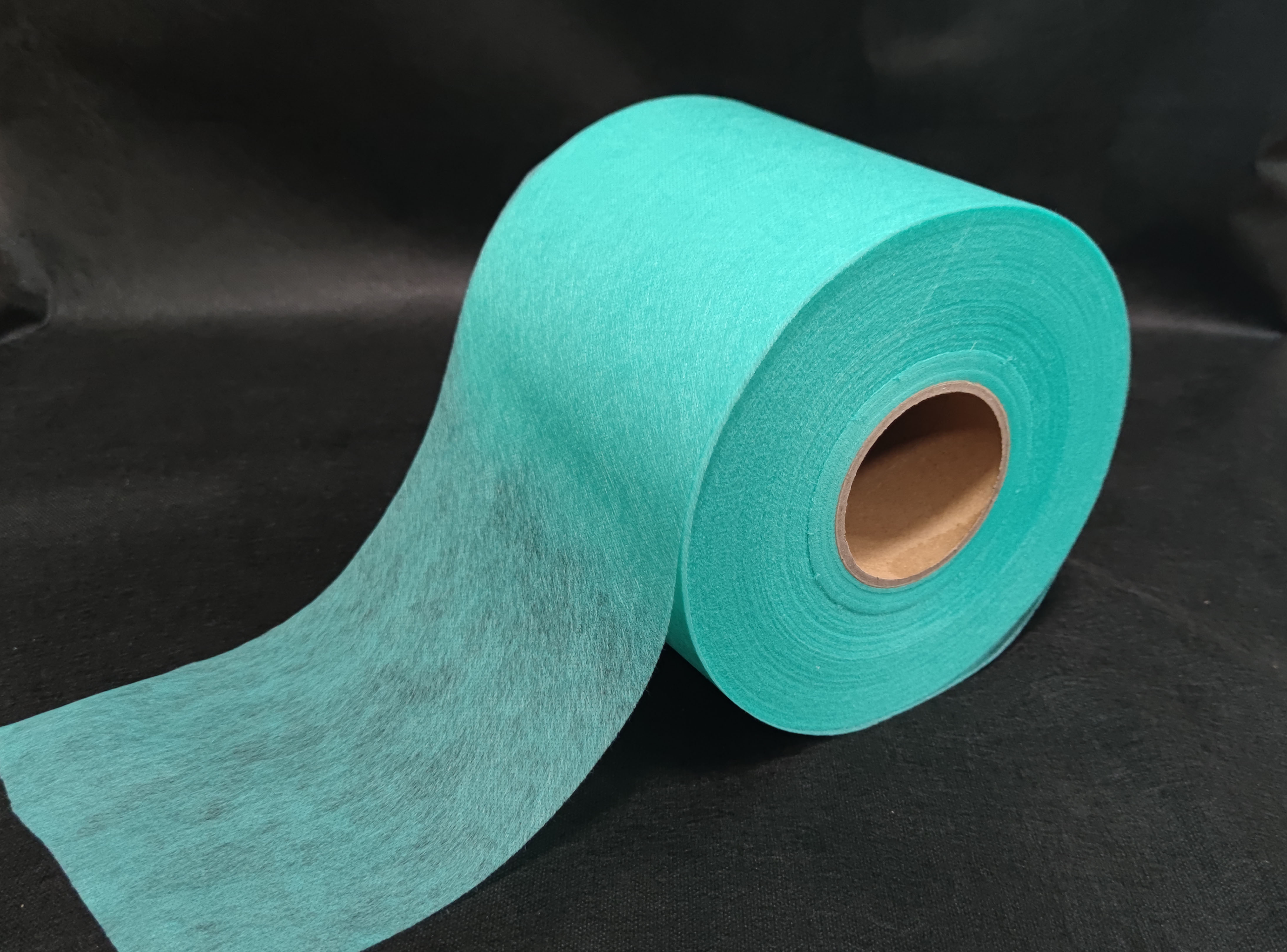

(Summary description)The following paragraph of this article will introduce the related production process of Melt-blown fabric. The production process of Melt-blown fabric is mainly divided into three steps: melt extrusion, melt-blown process, and electret treatment. Specifically, Melt-blown fabric uses high-speed hot air flow to draw the extruded polymer melt through the spinneret holes of the die nozzle. From this, microfibers are formed and collected on a condensate screen or drum, and at the same time self-bond to become a Melt-blown fabric.

How the Melt-blown fabric is constructed

(Summary description)The following paragraph of this article will introduce the related production process of Melt-blown fabric. The production process of Melt-blown fabric is mainly divided into three steps: melt extrusion, melt-blown process, and electret treatment.

Specifically, Melt-blown fabric uses high-speed hot air flow to draw the extruded polymer melt through the spinneret holes of the die nozzle. From this, microfibers are formed and collected on a condensate screen or drum, and at the same time self-bond to become a Melt-blown fabric.

- Categories:Melt-blown fabric News

- Author:

- Origin:

- Time of issue:2023-03-23

- Views:

The following paragraph of this article will introduce the related production process of Melt-blown fabric. The production process of Melt-blown fabric is mainly divided into three steps: melt extrusion, melt-blown process, and electret treatment.

Specifically, Melt-blown fabric uses high-speed hot air flow to draw the extruded polymer melt through the spinneret holes of the die nozzle. From this, microfibers are formed and collected on a condensate screen or drum, and at the same time self-bond to become a Melt-blown fabric.

When making Melt-blown fabric, the machines used are more complex and the requirements for the raw materials used are more stringent.

The melt-blown fabric uses molten polymer (such as polypropylene), polypropylene is a thermoplastic synthetic resin with excellent performance, which is a colorless and translucent thermoplastic lightweight general-purpose plastic. The polypropylene used in Melt-blown fabric has chemical resistance, heat resistance, electrical insulation, high strength mechanical properties and good high wear resistance processing properties. Based on this property of polypropylene used in Melt-blown fabric, the raw material of melt-blown fabric can be sprayed from a mold with many small nozzles under the action of high pressure.

Summary: If the performance of the product in the production process is different from the above description, it is necessary to deeply consider whether the raw materials of Melt-blown fabric are irregular. It is recommended that when choosing the raw material for Melt-blown fabric, one should look for a qualified certified manufacturer.

How to Choose the Right Oil Absorbent Pads for your Business

The Top 10 Oil Absorbent Pads for Industrial Applications

The Benefits of Using Wholesale Oil Absorbent Pads in the Filtration Industry

Choose the Best Wholesale Oil Absorbent Pads for Your Industrial Needs

ADD:No.399 West Section Of Fucheng Avenue,Hi-Tech Zone,ChengDu,China

Key words:

Filter Material Adsorption Products Filter Adsorption Medical Accessories Medical Liquid Absorbent Pad Oil Absorbent Cotton Oil Absorbent Cord Graphene Respirator Mask Material PM2.5

©2021 Sichuan Juneng Filter Material Co.,ltd Copyright Powered by www.300.cn