Causes of brittleness during the production of wholesale Melt-blown fabric

- Categories:Melt-blown fabric News

- Author:

- Origin:

- Time of issue:2022-05-16

- Views:

(Summary description)1. Wholesale Melt-blown fabric is brittle during production because the screw of general small melt-blown equipment is relatively short and has no mixing function. The melting of wholesale Melt-blown fabric basically relies on heating, so the production temperature is relatively high , and the degradation of the material leads to the brittleness of the fabric.

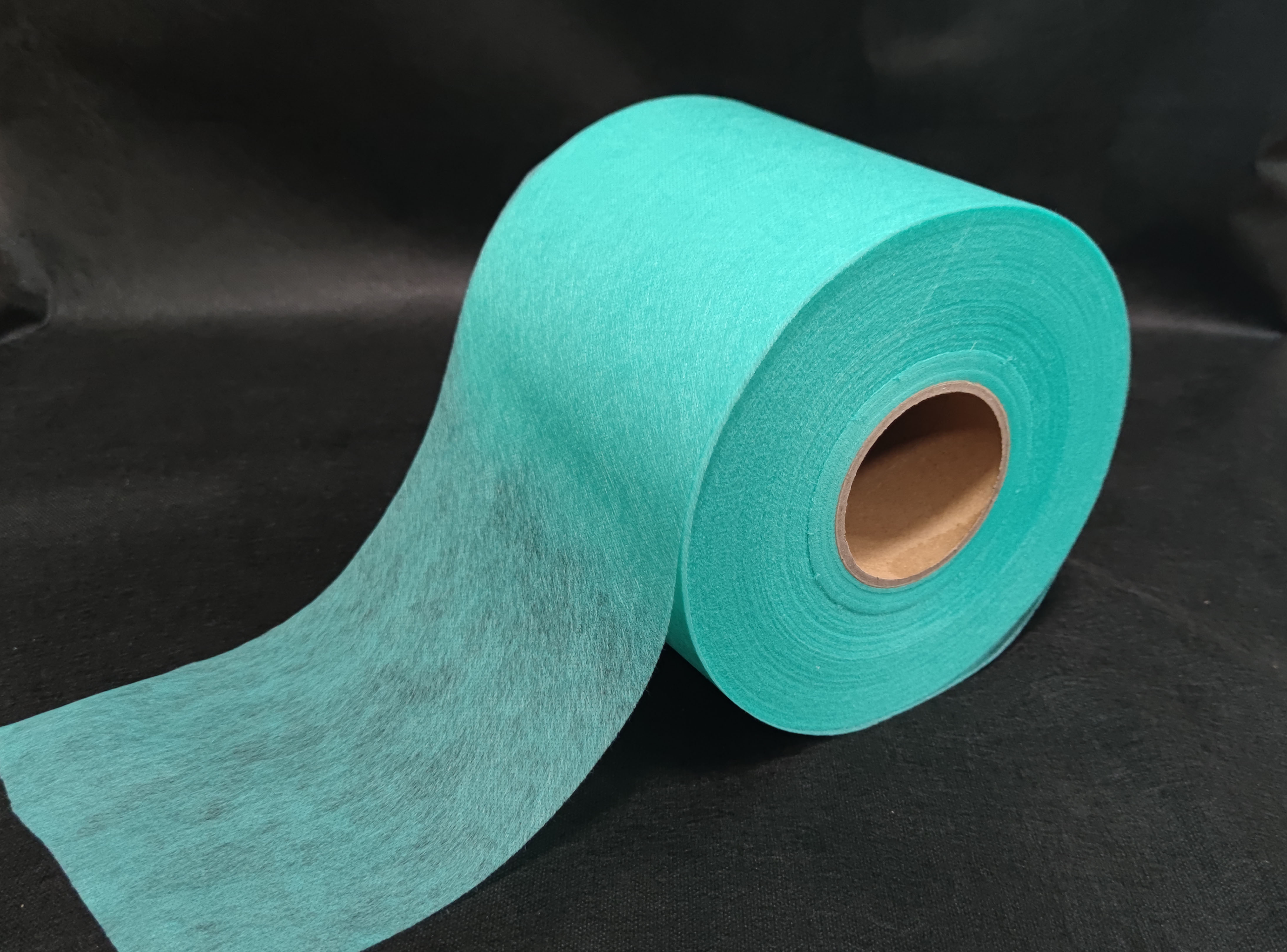

Causes of brittleness during the production of wholesale Melt-blown fabric

(Summary description)1. Wholesale Melt-blown fabric is brittle during production because the screw of general small melt-blown equipment is relatively short and has no mixing function. The melting of wholesale Melt-blown fabric basically relies on heating, so the production temperature is relatively high , and the degradation of the material leads to the brittleness of the fabric.

- Categories:Melt-blown fabric News

- Author:

- Origin:

- Time of issue:2022-05-16

- Views:

1. Wholesale Melt-blown fabric is brittle during production because the screw of general small melt-blown equipment is relatively short and has no mixing function. The melting of wholesale Melt-blown fabric basically relies on heating, so the production temperature is relatively high , and the degradation of the material leads to the brittleness of the fabric.

2. Wholesale Melt-blown fabric is brittle during production because of uneven spinning and insufficient cooling fan air volume, resulting in uneven heat dissipation, large internal stress, and high brittleness. Brittleness during the production of wholesale Melt-blown fabric can be improved by adjusting the melt volume of the extruder, adjusting the temperature of the hot air blower, and increasing the air volume of the cold air blower.

3. The reason for the brittleness of wholesale Melt-blown fabric during production From the aspect of raw materials, it may be that the spinning with a low melt index is used, and the silk is relatively thick. Wholesale Melt-blown fabric will become brittle and hard after complete crystallization within 24 to 48 hours.

4. The reasons for the brittleness of wholesale Melt-blown fabric during production are related to the high raw material and processing temperature. After the fibers in the wholesale Melt-blown fabric are produced, there is a process of secondary crystal rearrangement in the PP , which is actually severely heated in the screw, resulting in severe thermal degradation. If the initiator of the peroxide process in the wholesale Melt-blown fabric is not well controlled, such a problem is prone to occur.

5. The reason why the wholesale Melt-blown fabric is brittle during production maybe because the temperature of the newly produced melt-blown fabric is still there, especially in the large-drum spraying machine, which may not have a fan, and the temperature of the melt-blown fabric after winding is high. The greater the flexibility and toughness of plastic in a high-temperature environment, the more brittle the whole Melt-blown fabric will be after cooling, and an appropriate amount (3 ~ 5%) of a toughening agent can be added.

Through the above introduction and analysis of the reasons why wholesale Melt-blown fabric becomes brittle during production, hope it helps you.

Why Oil Absorbent Pads are Essential for a Safe and Clean Workplace

How to Choose the Right Oil Absorbent Pads for your Business

The Top 10 Oil Absorbent Pads for Industrial Applications

The Benefits of Using Wholesale Oil Absorbent Pads in the Filtration Industry

ADD:No.399 West Section Of Fucheng Avenue,Hi-Tech Zone,ChengDu,China

Key words:

Filter Material Adsorption Products Filter Adsorption Medical Accessories Medical Liquid Absorbent Pad Oil Absorbent Cotton Oil Absorbent Cord Graphene Respirator Mask Material PM2.5

©2021 Sichuan Juneng Filter Material Co.,ltd Copyright Powered by www.300.cn