Background and characteristics of spunbond

- Categories:Industry Information

- Author:

- Origin:

- Time of issue:2022-04-25

- Views:

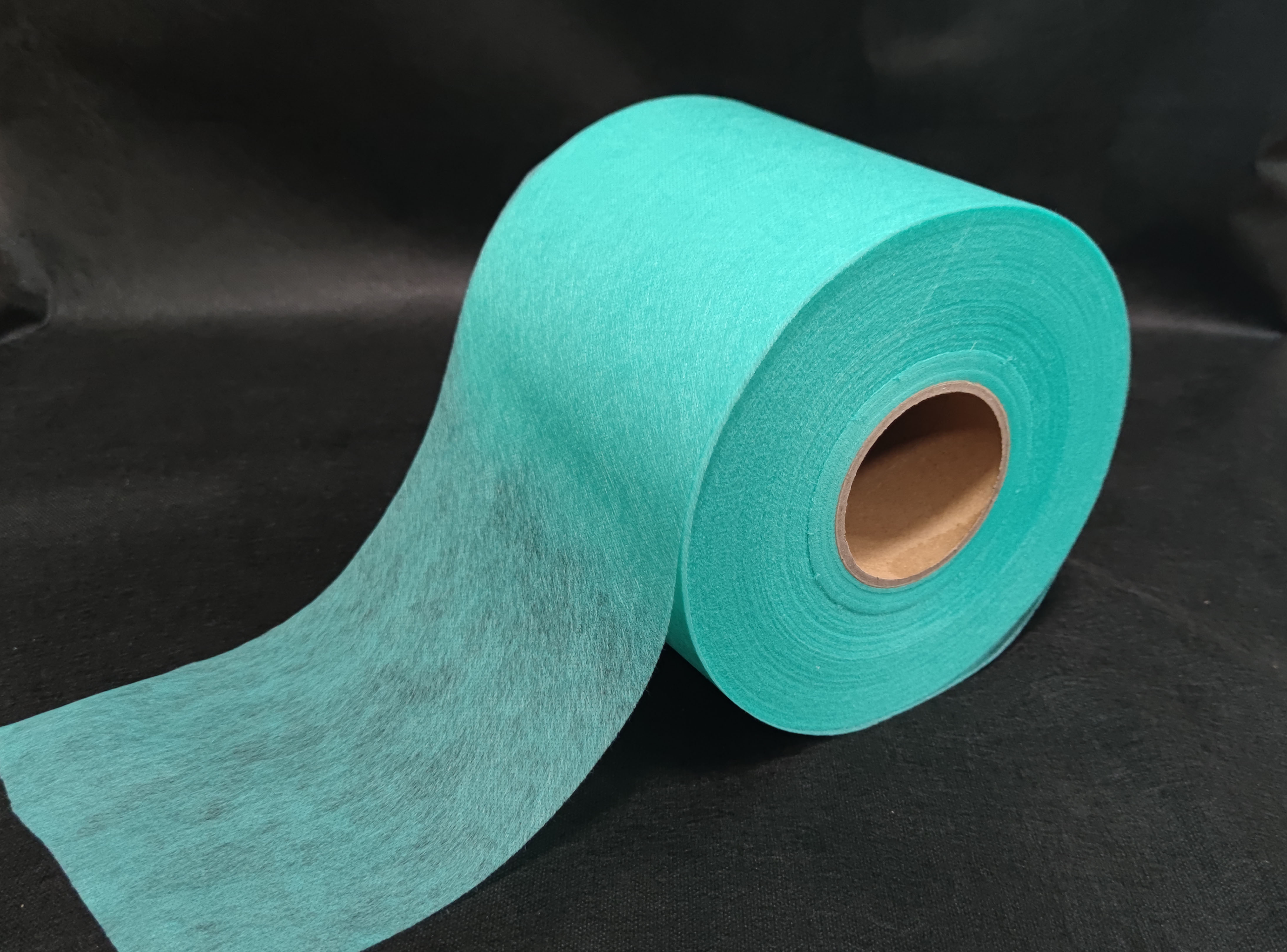

(Summary description)Polypropylene spunbond non-woven fabric is a kind of non-woven fabric, which is made of polypropylene as raw material, polymerized into a network by high-temperature drawing, and then bonded into a fabric by hot rolling. Because the technological process is simple, the output is large, and it is non-toxic and harmless to the human body. Therefore, it is widely used in sanitary materials and other fields.

Background and characteristics of spunbond

(Summary description)Polypropylene spunbond non-woven fabric is a kind of non-woven fabric, which is made of polypropylene as raw material, polymerized into a network by high-temperature drawing, and then bonded into a fabric by hot rolling. Because the technological process is simple, the output is large, and it is non-toxic and harmless to the human body. Therefore, it is widely used in sanitary materials and other fields.

- Categories:Industry Information

- Author:

- Origin:

- Time of issue:2022-04-25

- Views:

Polypropylene spunbond non-woven fabric is a kind of non-woven fabric, which is made of polypropylene as raw material, polymerized into a network by high-temperature drawing, and then bonded into a fabric by hot rolling. Because the technological process is simple, the output is large, and it is non-toxic and harmless to the human body. Therefore, it is widely used in sanitary materials and other fields.

In the non-woven manufacturing method, the spunbond method has obvious advantages in manufacturing technology, product performance and production efficiency. The spunbond method has achieved rapid development that has attracted worldwide attention in the past 20 years. About 40%~50% of non-woven fabrics are produced by the melt spinning method (including spunbond method, meltblown method and composite method of the two).

The important reason for the rapid development of the spunbond method is that it uses synthetic polymers as raw materials, and the method utilizes the principle of chemical fiber spinning. In the process of polymer spinning, continuous filaments are directly bonded after spinning to form a spunbond non-woven fabric.

In addition, spunbond nonwoven products have excellent mechanical properties, and their tensile strength, elongation at break, tear strength and other indicators are better than dry, wet, and meltblown nonwovens. Especially in recent years, the rapid development of spunbond method in production line scale, technology and equipment and product market development has greatly expanded the application field of spunbond non-woven fabrics.

Through the above introduction and analysis of Spunbond, hope it helps you.

How to Choose the Right Oil Absorbent Pads for your Business

The Top 10 Oil Absorbent Pads for Industrial Applications

The Benefits of Using Wholesale Oil Absorbent Pads in the Filtration Industry

Choose the Best Wholesale Oil Absorbent Pads for Your Industrial Needs

ADD:No.399 West Section Of Fucheng Avenue,Hi-Tech Zone,ChengDu,China

Key words:

Filter Material Adsorption Products Filter Adsorption Medical Accessories Medical Liquid Absorbent Pad Oil Absorbent Cotton Oil Absorbent Cord Graphene Respirator Mask Material PM2.5

©2021 Sichuan Juneng Filter Material Co.,ltd Copyright Powered by www.300.cn